Variable speed drive for hoist in mining industry

Tags: Mining industry

This application introduces variable speed technology in hoist machine system and related reform with variable speed drive in Coal Mine. It also explains regenerative energy type variable speed drive in coal mine.

Hoist machine is one of the most power-consuming and important equipments in mine. Its reliability influences production and personnel safety directly. Meanwhile, speed adjustment mode of Hoist machine is also a big factor for power consumption.

For long term, Hoist machine adopts rotor series resistance to adjust speed. It is low cost but with big torque, high consumption and complicated circuit. It damages contactor, resistor and electrical brush easily, which threatens system safety. With rapid development of power and motor technology, variable speed technology can solve above problems.

Operation performance of variable speed adjustment

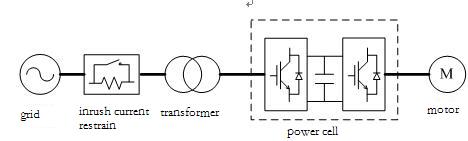

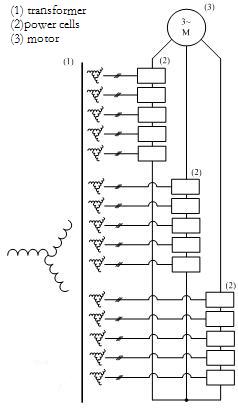

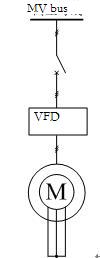

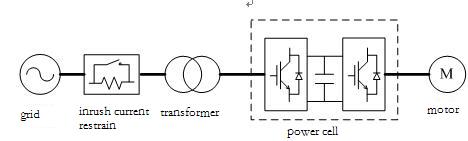

Short connect rotor winding of motor, convert power frequency voltage to voltage of some frequency through electrical components inside variable speed drive and the voltage is applied to stator winding of motor. It controls motor to run in expected speed by adjusting output voltage, frequency and phase position. Its circuit is shown following:

Compared with mode of rotor series resistance, variable speed technology has advantages of small current, stable motor operation, small torque pulsation, high controllability and energy saving.

Main control methods of variable speed technology are VVVF control, slip differential frequency control, direct torque control and vector control. vector control can realize decoupling control of magnetic flux and torque by modeling for motor, with the best control performance. Gozuk variable speed drive introduced in this paper adopts vector control. It is applicable for Hoist machine as its good control performance.

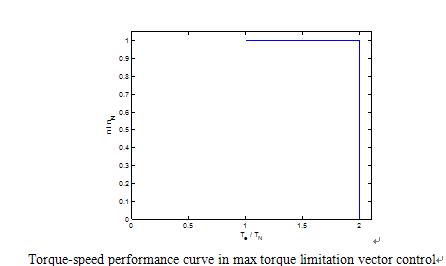

In vector control, variable speed drive can calculate magnetic-flux position, magnetic-flux amplitude, output torque and motor speed according to voltage signal, current signal, motor parameters and motor modeling. Then according to deviation of this speed and given speed, it adjusts output torque. If output torque is more than given "max torque", it outputs max torque.

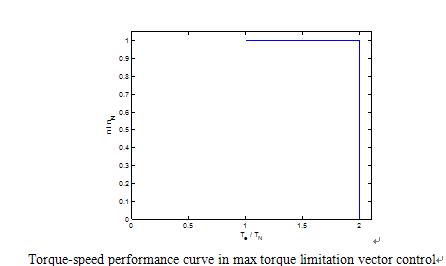

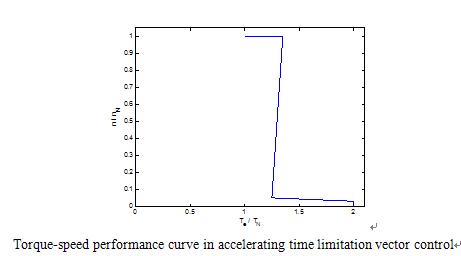

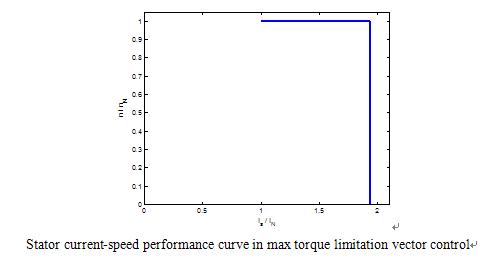

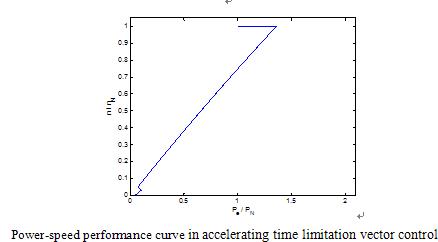

When given "accelerating time" is short enough, motor accelerates as per max torque. When given "max torque" is 2 times of rated torque, operation curve of motor accelerating in rated load is in following drawing. At the moment, motor is accelerating as per 2 times of rated torque. After accelerating, output torque is actual load torque, namely rated torque.

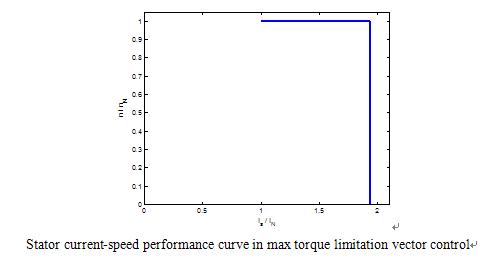

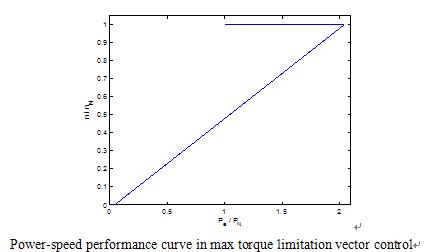

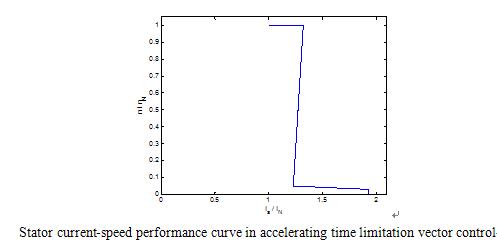

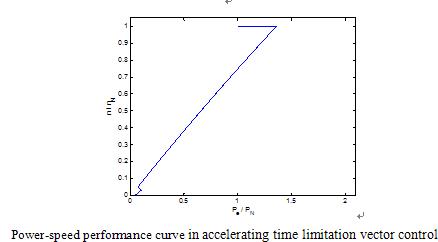

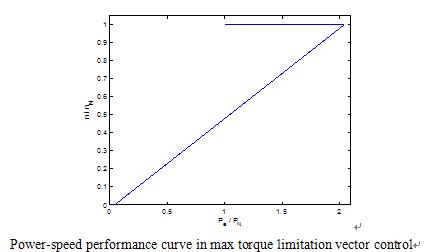

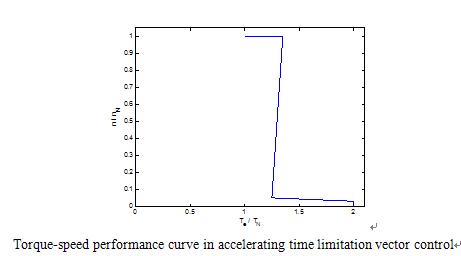

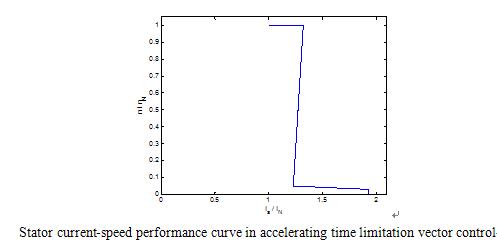

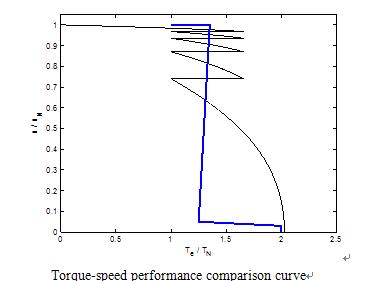

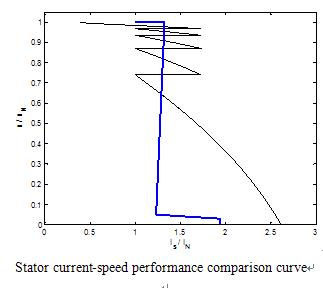

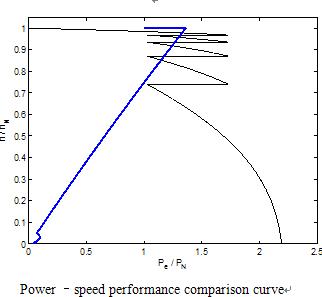

In actual application, Hoist machine usually has a limitation for max acceleration, so "accelerating time" is set according to expected acceleration. There is no need to reach given during accelerating as per above set. Following figures are accelerating curves of torque, power and current in rated torque. During starting Hoist machine, start variable speed drive first and then release brake. At the moment, most torque is applied to motor. Then motor accelerates according to set accelerating curve. Motor output torque is determined by load and set accelerating time, about 1.3 times of rated torque. Load torque is 1 time of rated torque, accelerating torque is 0.3 times of rated torque. Resistance of physical system and output torque of motor increases with speed rising. After reaching given speed (rated speed), motor stops to accelerate. Motor runs stably with load. Output torque is the same as load torque.

Comparison of two modes

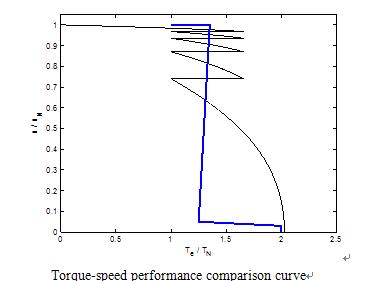

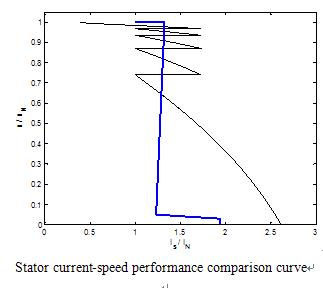

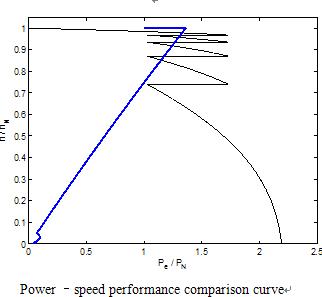

Compared with mode of rotor series resistance, in same load, variable speed adjustment has smaller motor torque pulsation, smaller motor current, and smaller absorbing power from grid, which means low degree of aging, stable accelerating and better comfortability.

Following is comparison curve. Blue line is variable speed mode (accelerating time limitation mode) , and black line is mode of rotor series resistance(rated current switch control mode).

Project introduction

1. Hoist

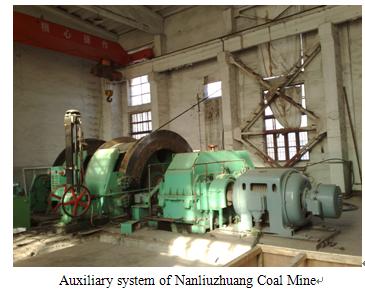

One of the oldest coal mine in China and has history of 130 years. In 2007, a company produced raw coal 29786200t and fancy coal 7548800t. Business income broke through 15 billion yuan.

This variable speed reform project is for a main Hoist and an auxiliary Hoist. Lift height is 211m and max speed is 3.27m/s, minimum speed is 0.5m/s. Main motor is 200kW/6kV, auxiliary motor is 280kW/6kV. Reduction ratio of reducer is 30. Original resistance level is 8.

Before reform with variable speed drive, motor vibration was big during starting. Control performance was not good in low speed stage and accelerating/decelerating stage, with big torque pulsation, bad stability and comfortability. Because of frequent start/stop, resistance loss was great. In addition, complicated circuit of rotor series resistance affected production efficiency. There were also disadvantages of big installation space, high heat and big noise for mode of series resistance.

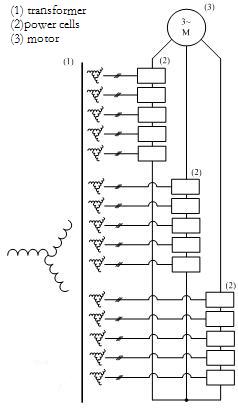

2. Variable speed drive structure

Two sets variable speed drives apply in this project, they are 6kV, 35A, 320kW, 400kVA.

The variable speed drive adopts IGBT bridge, with regenerative capacity of 100% power. Energy returns to power grid during decelerating brake and applies to other equipments of the plant, which lowers whole power consumption, applicable to four quadrants operation, such as Hoist machine.

Vector control variable speed drive makes decoupling control for motor magnetic flux and torque, can realize zero speed 200% torque start-up, frequent quick start/stop, and quick accelerating/decelerating.

The variable speed drive makes special design for Hoist machine load, makes its overload capacity 200% for 60s, reaching site requirement.

3. Reform

Two Hoist machines reformed with variable speed drive on 20th, January 2009. it pre-operated on 29th, January and run consecutively for 2 months without fault till this paper reported.

After reform with variable speed drive, Hoist machines can be controlled smoothly during accelerating and decelerating. Cable swing is down and personnel comfortability is improved. Motor start current and vibration is reduced greatly. Power consumption caused by series resistance can be saved. It also overcomes disadvantages of easy-damage of electrical brush and contactor. variable speed drive lowers fault and accident rate, brings benefits for plant. In addition, problems of series resistance are also solved, such as big installation space, high heat and big noise.

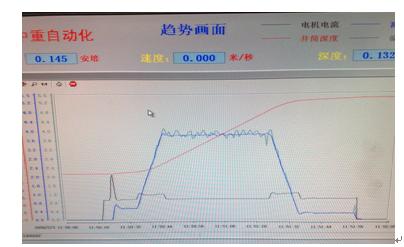

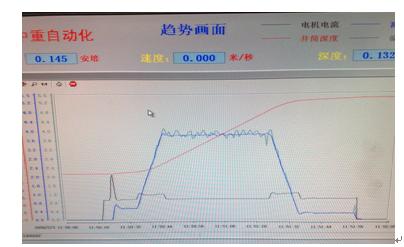

Operation curve:

The red: depth of wellbore

The black: motor stator current

The blue: actual motor speed

The green: motor speed measured by code wheel.

Because code wheel is in low speed side of reducer, there is a big deviation.

Conclusion

This application analyses operation performance in mode of variable speed drive and series resistance. In the same load, compared with rotor series resistance mode, variable speed drive control mode has small torque pulsation, small current and low power consumption in low speed stage. variable speed drive reduces vibration, wear and tear, with a considerable energy-saving effect.

Successful operation performance of two variable speed drives indicates that variable speed drive heightens stability and comfortability, lowers cable swing and start-up current, improves reliability, safety and efficiency.

Hoist machine is one of the most power-consuming and important equipments in mine. Its reliability influences production and personnel safety directly. Meanwhile, speed adjustment mode of Hoist machine is also a big factor for power consumption.

For long term, Hoist machine adopts rotor series resistance to adjust speed. It is low cost but with big torque, high consumption and complicated circuit. It damages contactor, resistor and electrical brush easily, which threatens system safety. With rapid development of power and motor technology, variable speed technology can solve above problems.

Operation performance of variable speed adjustment

Short connect rotor winding of motor, convert power frequency voltage to voltage of some frequency through electrical components inside variable speed drive and the voltage is applied to stator winding of motor. It controls motor to run in expected speed by adjusting output voltage, frequency and phase position. Its circuit is shown following:

Compared with mode of rotor series resistance, variable speed technology has advantages of small current, stable motor operation, small torque pulsation, high controllability and energy saving.

Main control methods of variable speed technology are VVVF control, slip differential frequency control, direct torque control and vector control. vector control can realize decoupling control of magnetic flux and torque by modeling for motor, with the best control performance. Gozuk variable speed drive introduced in this paper adopts vector control. It is applicable for Hoist machine as its good control performance.

In vector control, variable speed drive can calculate magnetic-flux position, magnetic-flux amplitude, output torque and motor speed according to voltage signal, current signal, motor parameters and motor modeling. Then according to deviation of this speed and given speed, it adjusts output torque. If output torque is more than given "max torque", it outputs max torque.

When given "accelerating time" is short enough, motor accelerates as per max torque. When given "max torque" is 2 times of rated torque, operation curve of motor accelerating in rated load is in following drawing. At the moment, motor is accelerating as per 2 times of rated torque. After accelerating, output torque is actual load torque, namely rated torque.

In actual application, Hoist machine usually has a limitation for max acceleration, so "accelerating time" is set according to expected acceleration. There is no need to reach given during accelerating as per above set. Following figures are accelerating curves of torque, power and current in rated torque. During starting Hoist machine, start variable speed drive first and then release brake. At the moment, most torque is applied to motor. Then motor accelerates according to set accelerating curve. Motor output torque is determined by load and set accelerating time, about 1.3 times of rated torque. Load torque is 1 time of rated torque, accelerating torque is 0.3 times of rated torque. Resistance of physical system and output torque of motor increases with speed rising. After reaching given speed (rated speed), motor stops to accelerate. Motor runs stably with load. Output torque is the same as load torque.

Comparison of two modes

Compared with mode of rotor series resistance, in same load, variable speed adjustment has smaller motor torque pulsation, smaller motor current, and smaller absorbing power from grid, which means low degree of aging, stable accelerating and better comfortability.

Following is comparison curve. Blue line is variable speed mode (accelerating time limitation mode) , and black line is mode of rotor series resistance(rated current switch control mode).

Project introduction

1. Hoist

One of the oldest coal mine in China and has history of 130 years. In 2007, a company produced raw coal 29786200t and fancy coal 7548800t. Business income broke through 15 billion yuan.

This variable speed reform project is for a main Hoist and an auxiliary Hoist. Lift height is 211m and max speed is 3.27m/s, minimum speed is 0.5m/s. Main motor is 200kW/6kV, auxiliary motor is 280kW/6kV. Reduction ratio of reducer is 30. Original resistance level is 8.

Before reform with variable speed drive, motor vibration was big during starting. Control performance was not good in low speed stage and accelerating/decelerating stage, with big torque pulsation, bad stability and comfortability. Because of frequent start/stop, resistance loss was great. In addition, complicated circuit of rotor series resistance affected production efficiency. There were also disadvantages of big installation space, high heat and big noise for mode of series resistance.

2. Variable speed drive structure

Two sets variable speed drives apply in this project, they are 6kV, 35A, 320kW, 400kVA.

The variable speed drive adopts IGBT bridge, with regenerative capacity of 100% power. Energy returns to power grid during decelerating brake and applies to other equipments of the plant, which lowers whole power consumption, applicable to four quadrants operation, such as Hoist machine.

Vector control variable speed drive makes decoupling control for motor magnetic flux and torque, can realize zero speed 200% torque start-up, frequent quick start/stop, and quick accelerating/decelerating.

The variable speed drive makes special design for Hoist machine load, makes its overload capacity 200% for 60s, reaching site requirement.

3. Reform

Two Hoist machines reformed with variable speed drive on 20th, January 2009. it pre-operated on 29th, January and run consecutively for 2 months without fault till this paper reported.

After reform with variable speed drive, Hoist machines can be controlled smoothly during accelerating and decelerating. Cable swing is down and personnel comfortability is improved. Motor start current and vibration is reduced greatly. Power consumption caused by series resistance can be saved. It also overcomes disadvantages of easy-damage of electrical brush and contactor. variable speed drive lowers fault and accident rate, brings benefits for plant. In addition, problems of series resistance are also solved, such as big installation space, high heat and big noise.

Operation curve:

The red: depth of wellbore

The black: motor stator current

The blue: actual motor speed

The green: motor speed measured by code wheel.

Because code wheel is in low speed side of reducer, there is a big deviation.

Conclusion

This application analyses operation performance in mode of variable speed drive and series resistance. In the same load, compared with rotor series resistance mode, variable speed drive control mode has small torque pulsation, small current and low power consumption in low speed stage. variable speed drive reduces vibration, wear and tear, with a considerable energy-saving effect.

Successful operation performance of two variable speed drives indicates that variable speed drive heightens stability and comfortability, lowers cable swing and start-up current, improves reliability, safety and efficiency.

<- - I have an Opinion - ->