Variable speed drive in mining industry (coal)

Tags: Mining industry

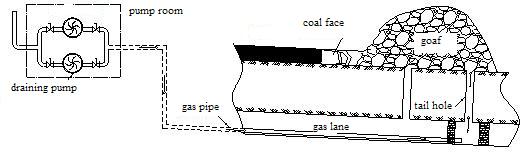

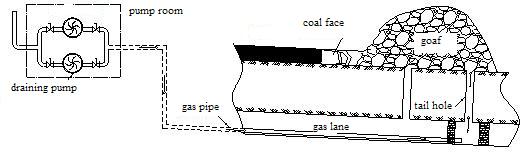

There is a drain pipe of diameter 1000mm which is in gas lane of goaf bottom and comes to pump room. Pump is water ring vacuum pump. Please see technical diagram in following:

Here are parameters:

Pump parameters

Rated speed: 340r/min

Max drain flow: 635m3/min

Ultimate vacuum: 160MPa

Motor parameters

Rated power: 900kW

Rated voltage: 6kV

Rated current: 104.2A

Rated speed : 1483r/min

Power factor: 0.87

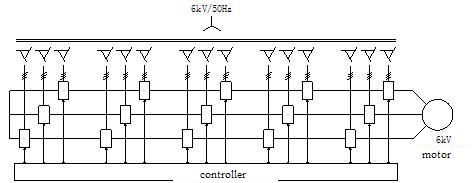

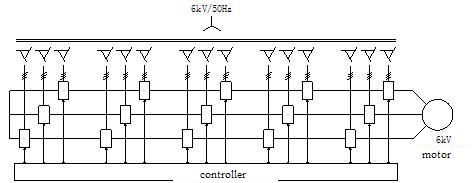

Variable speed drive is composed of phase-shifting transformer, power cells and controller. Five power cells make up of a phase. Please see following diagram:

Power: 900kW

Rated output current: 110A

Input power factor: 0.95

variable speed drive efficiency:>0.96

Frequency resolution: 0.01Hz

Overload capacity: 120% for 1min and 150% immediately

Analogue input: 0~10V/4~20mA

Analogue output: 0~10V/4~20mA

Accelerating/decelerating time: 0.1~3000s

Digital input/output: 4 routes output/4 routes input

Cooling type: air cooling

System Main circuit

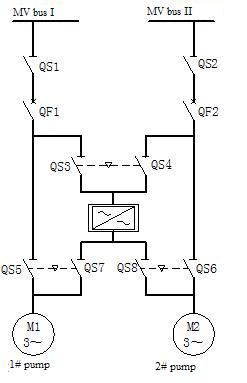

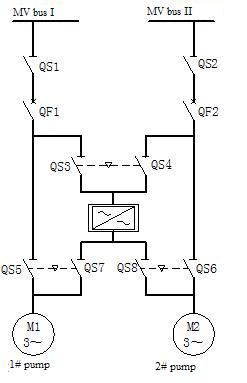

Gas drain pump as well as main ventilation blower is main equipment in coal mine. In the light of safety regulation of coal mine, power is supplied by double routes. There are two pumps in room, one work and one standby. So scheme of "variable speed drive drive two" is selected. Its main diagram is following:

System can implement following operation modes:

a. With bus I supplying power, variable speed drive drives 1# pump, consisting of QS1, QF1, QS3, QS7.

b. With bus I supplying power, variable speed drive drives 2# pump, consisting of QS1, QF1, QS3, QS8.

c. With bus II supplying power, variable speed drive drives 2# pump, consisting of QS2, QF2, QS4, QS8.

d. With bus II supplying power, variable speed drive drives 1# pump, consisting of QS2, QF2, QS4, QS7.

e. With bus I supplying power, 1# pump runs in direct on line, consisting of QS1, QF1, QF5.

f. With bus II supplying power, 2# pump runs in direct on line, consisting of QS2, QF2, QS6.

Variable speed drive installation and commissioning

a. Draining gas of pump room is inflammable and explosive gas. All equipments in pump room are explosion proof. But variable speed drive is non-explosion proof device, it should be installed in an isolated room.

b. After installation and commissioning, gas draining system puts into service. Make statistic for the system when pump runs in 30~50Hz. Here are average values:

1. It meets demand of working condition

Goaf draining system is used to control gas amount not beyond safety regulation, thereby ensuring safe production of mine. In the light of survey, pump usually runs in 35~45Hz. Operation frequency is determined by distance of coal face and drain tail hole. When coal face is close to drain tail hole, frequency is low. Otherwise, frequency is high. Measure gas parameters periodically, analyze and determine operating frequency of pump. In this way, system can ensure gas amount not beyond safety regulation, and ensure fresh air not to enter goaf, avoiding natural fire accident. So raw coal production is enhanced a lot.

2. Soft start

Because of big power, start time is long and start current is big during direct start, which threatens motor insulation and also brings impact on power gird and mechanism. Variable speed drive can implement soft start and soft stop with following advantages:

3. Energy saving effect

4. Energy saving calculation

Pump usually runs in 35~45Hz and mostly in 45Hz. Average work time is 350 days(maintenance needs one day per month),

a. power consumption in 50Hz:

b. power consumption in 45Hz

c. yearly energy saved:

Power price: 0.5yuan/kWh, so 707000yuan (USD103970)is saved.

5. Power factor is improved

Rated power factor of motor is 0.87. Variable speed drive can raise it up to 0.95. So power quality is heightened and power cost declines.

Conclusion

In the mining gas draining system, medium voltage variable speed drive controls gas amount of coal face and air return system effectively. It ensures safe production and saves considerable energy.

Here are parameters:

Pump parameters

Rated speed: 340r/min

Max drain flow: 635m3/min

Ultimate vacuum: 160MPa

Motor parameters

Rated power: 900kW

Rated voltage: 6kV

Rated current: 104.2A

Rated speed : 1483r/min

Power factor: 0.87

Variable speed drive structure

Variable speed drive is composed of phase-shifting transformer, power cells and controller. Five power cells make up of a phase. Please see following diagram:

Variable speed drive parameters

Power: 900kW

Rated output current: 110A

Input power factor: 0.95

variable speed drive efficiency:>0.96

Frequency resolution: 0.01Hz

Overload capacity: 120% for 1min and 150% immediately

Analogue input: 0~10V/4~20mA

Analogue output: 0~10V/4~20mA

Accelerating/decelerating time: 0.1~3000s

Digital input/output: 4 routes output/4 routes input

Cooling type: air cooling

System Main circuit

Gas drain pump as well as main ventilation blower is main equipment in coal mine. In the light of safety regulation of coal mine, power is supplied by double routes. There are two pumps in room, one work and one standby. So scheme of "variable speed drive drive two" is selected. Its main diagram is following:

System can implement following operation modes:

a. With bus I supplying power, variable speed drive drives 1# pump, consisting of QS1, QF1, QS3, QS7.

b. With bus I supplying power, variable speed drive drives 2# pump, consisting of QS1, QF1, QS3, QS8.

c. With bus II supplying power, variable speed drive drives 2# pump, consisting of QS2, QF2, QS4, QS8.

d. With bus II supplying power, variable speed drive drives 1# pump, consisting of QS2, QF2, QS4, QS7.

e. With bus I supplying power, 1# pump runs in direct on line, consisting of QS1, QF1, QF5.

f. With bus II supplying power, 2# pump runs in direct on line, consisting of QS2, QF2, QS6.

Variable speed drive installation and commissioning

a. Draining gas of pump room is inflammable and explosive gas. All equipments in pump room are explosion proof. But variable speed drive is non-explosion proof device, it should be installed in an isolated room.

b. After installation and commissioning, gas draining system puts into service. Make statistic for the system when pump runs in 30~50Hz. Here are average values:

| SR | frequency (Hz) | Motor parameters | Gas parameters | |||

| voltage (kV) | Current (A) | Power (kW) | Draining flow (m3/min) | Gas of coal face(%) | ||

| 1 | 30 | 3.59 | 36.1 | 206.4 | 398.75 | 1.58 |

| 2 | 35 | 4.48 | 46.3 | 338.4 | 401.28 | 0.86 |

| 3 | 40 | 4.91 | 54.6 | 430.9 | 403.45 | 0.67 |

| 4 | 45 | 5.24 | 62.2 | 542.84 | 404.14 | 0.3 |

| 5 | 50 | 6.084 | 68.76 | 710.96 | 404.71 | 0.23 |

Variable speed drive effect in gas draining system

1. It meets demand of working condition

Goaf draining system is used to control gas amount not beyond safety regulation, thereby ensuring safe production of mine. In the light of survey, pump usually runs in 35~45Hz. Operation frequency is determined by distance of coal face and drain tail hole. When coal face is close to drain tail hole, frequency is low. Otherwise, frequency is high. Measure gas parameters periodically, analyze and determine operating frequency of pump. In this way, system can ensure gas amount not beyond safety regulation, and ensure fresh air not to enter goaf, avoiding natural fire accident. So raw coal production is enhanced a lot.

2. Soft start

Because of big power, start time is long and start current is big during direct start, which threatens motor insulation and also brings impact on power gird and mechanism. Variable speed drive can implement soft start and soft stop with following advantages:

- Impact on motor and other equipments during start and stop is eliminated. Lifetime of pump and motor is extended.

- variable speed drive control limits impact on power grid during start, reduces peak start power loss.

- With speed down, lubrication condition of equipments is improved and driving mechanism failure is reduced.

3. Energy saving effect

4. Energy saving calculation

Pump usually runs in 35~45Hz and mostly in 45Hz. Average work time is 350 days(maintenance needs one day per month),

a. power consumption in 50Hz:

b. power consumption in 45Hz

c. yearly energy saved:

Power price: 0.5yuan/kWh, so 707000yuan (USD103970)is saved.

5. Power factor is improved

Rated power factor of motor is 0.87. Variable speed drive can raise it up to 0.95. So power quality is heightened and power cost declines.

Conclusion

In the mining gas draining system, medium voltage variable speed drive controls gas amount of coal face and air return system effectively. It ensures safe production and saves considerable energy.

<- - I have an Opinion - ->